What is the difference between air-blown fiber and air-blown cable?

With more and more data capacity required to support advanced computing such as AI and quantum computing, optical fiber demand continues to rise. Fortune Business Insights’ March 2025 report predicted that the world’s optical fiber market size will grow from $8.96 billion in 2025 to $17.84 billion by 2032, with North America making up nearly 40 percent of the global market.

The current optical fiber market in North America features many manufacturers offering an array of products especially designed for a wide range of project needs. Microduct cable is among the innovations gaining traction in North America following decades of refinement and successful installations in Europe. On the other hand, air-blown fiber (ABF) has long been a North American mainstay, ever since Sumitomo Electric Lightwave pioneered the FutureFLEX® Air-Blown Fiber® System more than 30 years ago.

What air-blown fiber and microduct cable have in common is a similar installation method: air pressure. Whereas conventional products require cable to be pulled through ducts, air-blown products use jetting equipment and air pressure to propel ABF and microduct cable through the ducts.

Pull Method: Used for Conventional Cables

This method involves pulling a fiber optic cable through pre-installed underground or aerial ducts. While this allows you to choose between manually pulling the cable or using a reeling machine to assist, it is often completed with machine assistance, particularly when deploying over longer OSP distances. Both manual and machine-assisted pulling require frequent “intermediate assist points” at which cables are pulled through the duct, placed into handholds or access points, and spliced together, often necessitating “figure-eight” looping to prevent cable twisting when the duct changes direction. This process requires additional workers and equipment movement from location to location resulting in additional deployment costs and time at an average pull rate of 50 feet per minute.

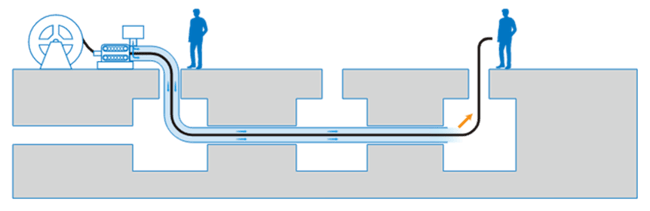

Jetted Method: Used for Air-blown Fiber and Air-Blown Cables

Jetted technology, pre-terminated or not, is considered the less disruptive option thanks to its minimal touch points throughout the deployment This method is achieved by jetting a cable through an underground duct (aerial ducts can be used for short distances) using compressed air while simultaneously pushing the cable into the duct. This is only possible with the use of machinery. Considerably faster than pulling cable, jetting cables move at 150 feet per minute or higher speeds. Jetting allows for a smooth transition through duct turns and curves by reducing friction and placing less strain on the cable, allowing for deployment lengths into the thousands of feet. This eliminates many, if not all, “intermediate assist points” and associated labor.

A Comparison of Jetted (Air-Blown) Fiber and Cable Solutions

Since both air-blown fiber and microduct cable use jetting equipment to blow optical fiber capacity through ducts, the question that often comes up is “are these the same product?”

The answer is no.

There is a clear difference, or rather four distinct ways in which these solutions differ. The following tables explore these differences as they relate to products in Sumitomo Electric Lightwave’s portfolio; other manufacturers’ offerings may vary.

Both air-blown fiber and microduct cable systems are great options for using limited conduit space to maximize capacity in optical fiber installations. By utilizing the existing pathway, air-blown technologies enable network managers to easily expand or modify optical fiber configuration in the future. The cost savings are realized up front through significantly faster installations as compared to conventional cable pulls.

The key to optimizing conduit space, project costs, and installation timelines is a matter of choosing the mix of products that best fits your unique project needs. Sumitomo Electric Lightwave offers a broad optical fiber cable and connectivity portfolio that enables a tailored solution for your next project. Please visit our website or contact me for more information.

|

About the author: Yuko Agano is a product manager supporting air-blown fiber and cable technologies at Sumitomo Electric Lightwave. She has been with the company for more than 10 years. |